Jet Dust Collector Progress

180 minutes

Cutting Wood and Making a Mess

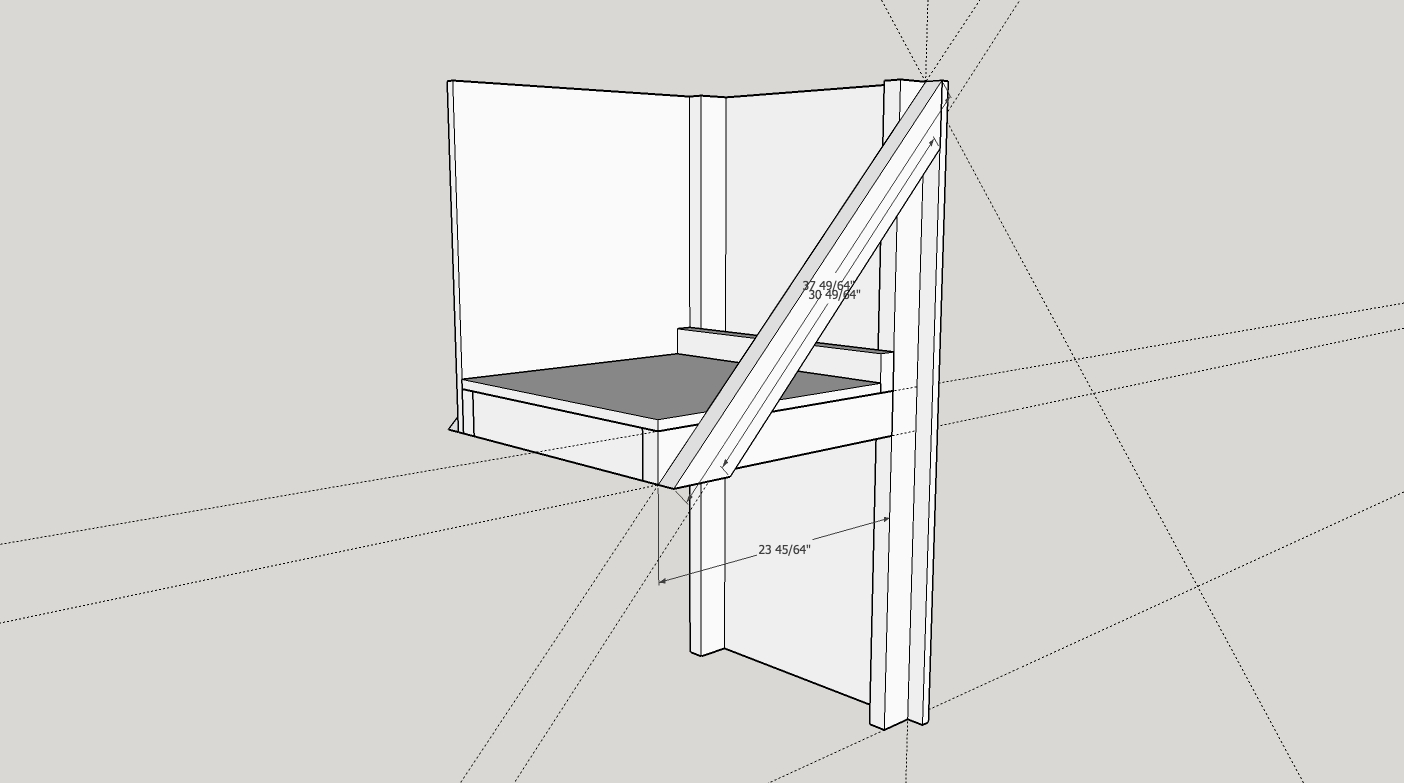

I failed to snap measurements to 1/4 of an inch in SketchUp which make the cuts come out with a resolution of 64ths, which isn’t terribly useful for the reality of cutting dimensional lumber. I improvised and used the design, but with some modifications.

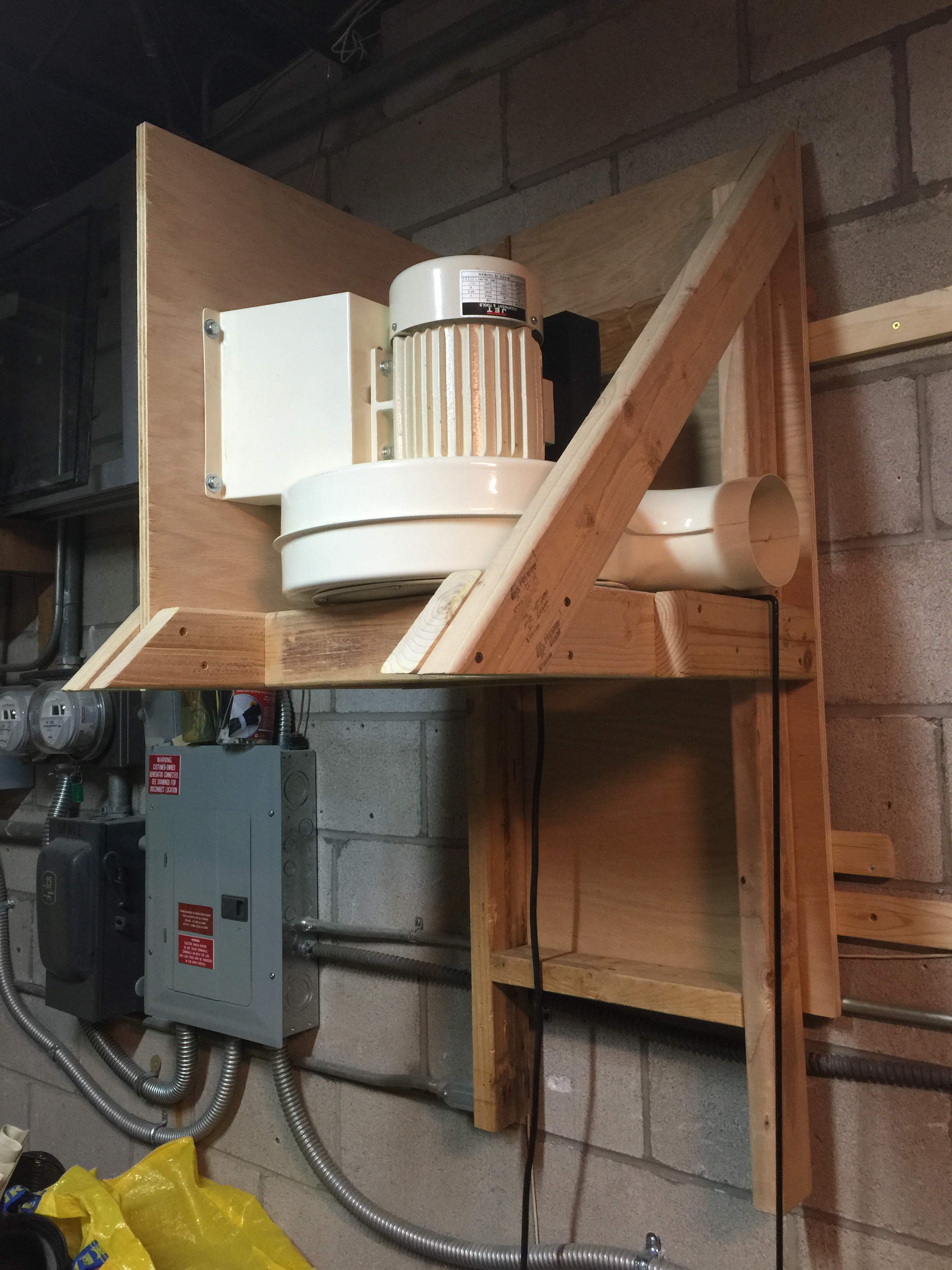

I first rounded the diagonal parts to the nearest inch and measured everything from there by hand as I progressed. I also used only the scrap pieces that I had on hand in my garage to assemble the wall mount. Practically, I had more than enough 2x4 lumber, but I didn’t have the right dimensions of 3/4 plywood. There are gaps in the top and the bottom because the plywood I had on hand wasn’t long enough for the design.

I hung the whole assembly on a 1x6 cut into French cleats, the part on the wall was already in place and made out of pine while the piece on the back of the wall mount is made out of oak I recycled from a broken couch someone left on a street corner years ago. Once mounted on the wall everything was very sturdy and supported my weight as I hung from the front of the structure.

The bottom support isn’t screwed in yet because I’ll likely use it to help me support the cyclone, and I need to figure out the right location to add 2x4s to support the cone of the cyclone.

Next Steps

These are the things I’ll be posting about, but also reminding myself here.

- Mount the cyclone under the blower.

- Order the air filter and come up with a way to hang it next to the dust collector.

- Mount the chip barrel to the cyclone.

- Design hose track for CNC machine

- Mount the Dust Collector remote

- Order dust shoe for CNC router.