Testing CAM programs with SVG Part I (MakerCAM)

90 minutesA Simple Drawing

I would like to do some experiments with some simple SVG files and a few different CAM packages. To start with I’m created what I believe to be the simplest input document that I could think of which is a hand coded SVG square:

<svg xmlns="http://www.w3.org/2000/svg"

xmlns:xlink="http://www.w3.org/1999/xlink">

<rect x="0" y="0" width="100" height="100" style="fill:red;" />

</svg>The cut will be along the outside of the square and it will be cut out of the material.

Physical Constraints

- The virtual material I plan to cut through will be 5mm thick plywood.

- I will also be using a 1/8 inch single flute, which may be complete garbage,

- Finally I’ll be assuming a spindle that runs at 12000 rpm.

Cam Software

MakerCam

- File => Open SVG File

- CAM => profile operation

- CAM => calculate all

- CAM => calculate all

- CAM => export gcode

Resulting GCODE

1 (Generated by PartKam Version 0.05)

2

3 G21 G90 G40

4

5 (single cut)

6 G0 Z15

7 T0 M6

8 G17

9 M3

10 G0 X-1.5875634517766497 Y0

11 G1 Z-1.5 F1200

12 G1 X-1.5862944162436547 Y-35.276649746192895 F2473

13 G3 X0 Y-36.86548223350254 I1.5862944162436547 J0

14 G1 X35.276649746192895 Y-36.86548223350254

15 G3 X36.86548223350254 Y-35.276649746192895 I0 J1.5862944162436547

16 G1 X36.86548223350254 Y0

17 G3 X35.276649746192895 Y1.5862944162436547 I-1.5862944162436547 J0

18 G1 X0 Y1.5862944162436547

19 G3 X-1.5862944162436547 Y0 I0 J-1.5862944162436547

20 G1 Z-3 F1200

21 G1 X-1.5862944162436547 Y-35.276649746192895 F2473

22 G3 X0 Y-36.86548223350254 I1.5862944162436547 J0

23 G1 X35.276649746192895 Y-36.86548223350254

24 G3 X36.86548223350254 Y-35.276649746192895 I0 J1.5862944162436547

25 G1 X36.86548223350254 Y0

26 G3 X35.276649746192895 Y1.5862944162436547 I-1.5862944162436547 J0

27 G1 X0 Y1.5862944162436547

28 G3 X-1.5862944162436547 Y0 I0 J-1.5862944162436547

29 G1 Z-4.5 F1200

30 G1 X-1.5862944162436547 Y-35.276649746192895 F2473

31 G3 X0 Y-36.86548223350254 I1.5862944162436547 J0

32 G1 X35.276649746192895 Y-36.86548223350254

33 G3 X36.86548223350254 Y-35.276649746192895 I0 J1.5862944162436547

34 G1 X36.86548223350254 Y0

35 G3 X35.276649746192895 Y1.5862944162436547 I-1.5862944162436547 J0

36 G1 X0 Y1.5862944162436547

37 G3 X-1.5862944162436547 Y0 I0 J-1.5862944162436547

38 G1 Z-5 F1200

39 G1 X-1.5862944162436547 Y-35.276649746192895 F2473

40 G3 X0 Y-36.86548223350254 I1.5862944162436547 J0

41 G1 X35.276649746192895 Y-36.86548223350254

42 G3 X36.86548223350254 Y-35.276649746192895 I0 J1.5862944162436547

43 G1 X36.86548223350254 Y0

44 G3 X35.276649746192895 Y1.5862944162436547 I-1.5862944162436547 J0

45 G1 X0 Y1.5862944162436547

46 G3 X-1.5862944162436547 Y0 I0 J-1.5862944162436547

47 G0 Z15

48 M5

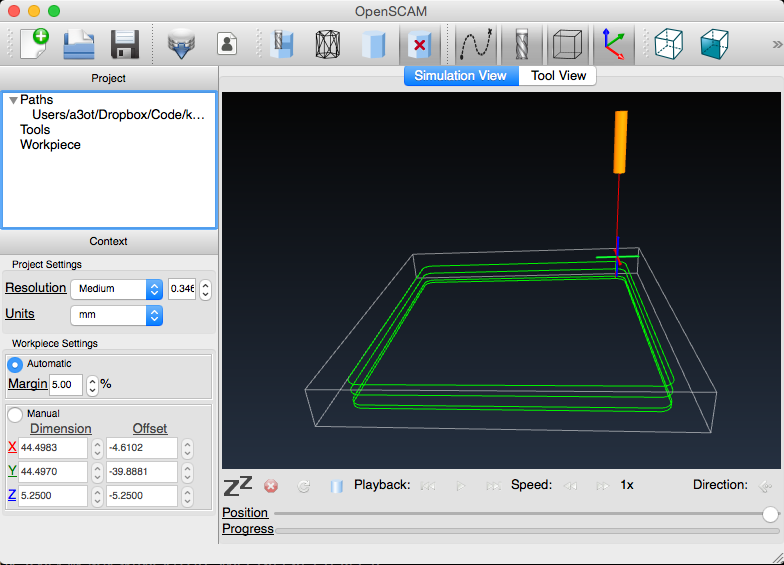

49 M30OpenSCAM Rendered Output

Future Posts

I’ll be evaluating other CAM software and their resulting GCODE. I’ll also be exploring how the differences in the generated GCODE will effect the machining of the part.